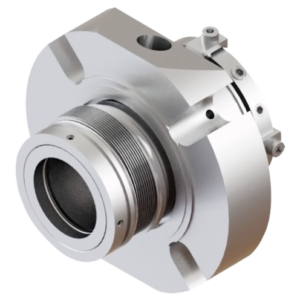

SPX Single Seals Split

Description

Typical Industrial Applications

- Agitators

- Chemical Industry

- Centrifugal pumps

- Conveying pulp with stock pumps

- Cooling water pumps for energy generation

- Conveying timber to refiners with pumping screws

- Circulation of pulp-and-water mixtures in storage vessels

- Displacement pumps

- Process industry

- Petrochemical Industry

- Power Plant Technology

- Pulp and paper industry

- Pump stations for waste water treatment

1. Single seal in split configuration

2. Balanced design

3. Independent of direction of rotation

4. For plain shafts

5. Semi-cartridge construction

6. Built-in flushing connections

7. Designed with external pressurization

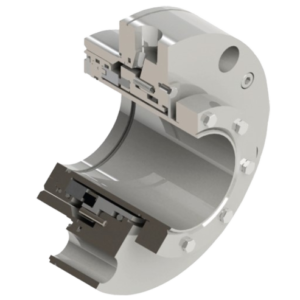

8. Factory assembled fully split single

seal, 2 x 2 segments

9. Stationary design with multiple springs

Technical Features

1. Economical to assemble as the complete dismantling of the equipment is not necessary to install the seal

2. Reduces down time due to ease in installation

3. Rugged seal construction

4. Distortion of the seat is avoided by mechanical decoupling of the clamping ring

5. Ease in installation and no modifications are required because the seal is located outside of the stuffing box

6. Due to the stationary design and the elastic seat mounting a high tolerance of shaft deflections can be accommodated

7. Low leakage is achieved by the elimination of secondary seals which eliminates leakage paths between split components

8. Shaft is protected by uniform torque transmission through the clamping ring which prevents damage caused by set screws

9. Springs are product protected to avoid contamination and clogging