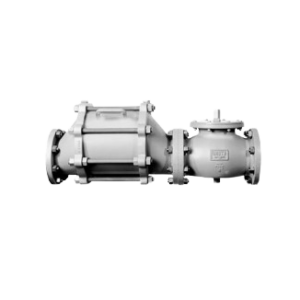

MODEL 8820A – Pressure/Vacuum Valve & Flame Arrester (pipe-away)

Description

The Model 8820A combination units are used for pressure and vacuum relief where vapors must be piped away. They are designed to protect your tank from damage created by overpressure or excessive vacuum, at the same time that they provide protection from externally caused sources of heat and ignition. The result is reduced emissions level and increased fire protection and safety.

The Groth model 8820A is a combination of the 1220A Pressure Vacuum Relief Valve and Groth Model 7618A Flame Arrester. The superior Buna-N seating diaphragms are standard on the valve to insure extra tight sealing to prevent sludge vapors escaping. Self draining housing body and drip rings protect seating surface from condensate and freezing.

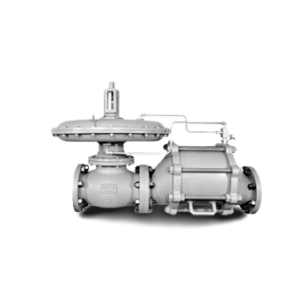

Features

The Model 8820A Pressure/Vacuum Relief Valve with flanged pipe-away outlet offers Groth’s special “cushioned air” seating. Superior performing fluoropolymer seating diaphragms are standard to minimize sticking caused by resinous vapors and atmospheric moisture. Self draining housings and drip rings protect seating surfaces from condensate and freezing.

End-of-Line

Flanged Outlet with or without Discharge Piping

- Gas Group: NEC D, IEC IIA

- Operating Temperature <= 140°F (60°C)

- Pre-Ignition Pressure = Atmosphere

- Discharge Piping Length <= 10 pipe diameters

IN-Line

- Gas Group: IEC IIA1, Methane

(includes most Biogas applications)- Operating Temperature <= 140°F (60°C)

- Pre-Ignition Pressure <= 1 psig

- Run-up Length <= 50 pipe diameters (2”)

- Run-up Length <= 20 pipe diameters (3”)

- Run-up Length <= 10 pipe diameters (4”–12”)