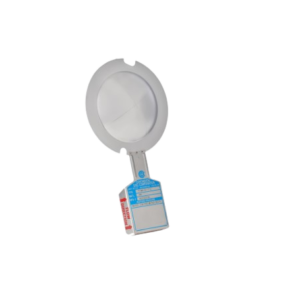

Clean-Sweep Assembly

Description

This holder is an ideal replacement for rupture disc assemblies installed off the leg of a pipe tee where product buildup could affect the proper operation of the rupture disc. With the CLEAN-SWEEP Assembly installed, the rupture disc mounts directly adjacent to the process flow.

The CLEAN-SWEEP Assembly eliminates the dead space in pipe-tee assemblies, as well as the pressure, temperature and material availability limitations caused by older, diaphragm valve body-based designs.

With the CLEAN-SWEEP, the rupture disc mounts directly on the body casting, adjacent to the process flow. It requires fewer sealed joints and greatly reduces the possibility of product buildup or dead space under the rupture disc.

Designed for operating pressures up to 1,440 psig (99,3 barg), the CLEAN-SWEEP Assembly is custom-machined to bolting classes of ASME, DIN, JIS or as specified by the customer. Alignment pins in the assembly inlet provide correct rupture disc orientation during installation. Once installed, the 3-Dimensional Flow Direction Tag, which is permanently attached to the rupture disc, is a visual reference that the rupture disc will discharge in the intended flow direction.

The CLEAN-SWEEP Assembly is designed to house either a Composite (CF) or MICRO X (CF) Rupture Disc, both of which have a flat seat configuration.